Bota Biofoundry Platform

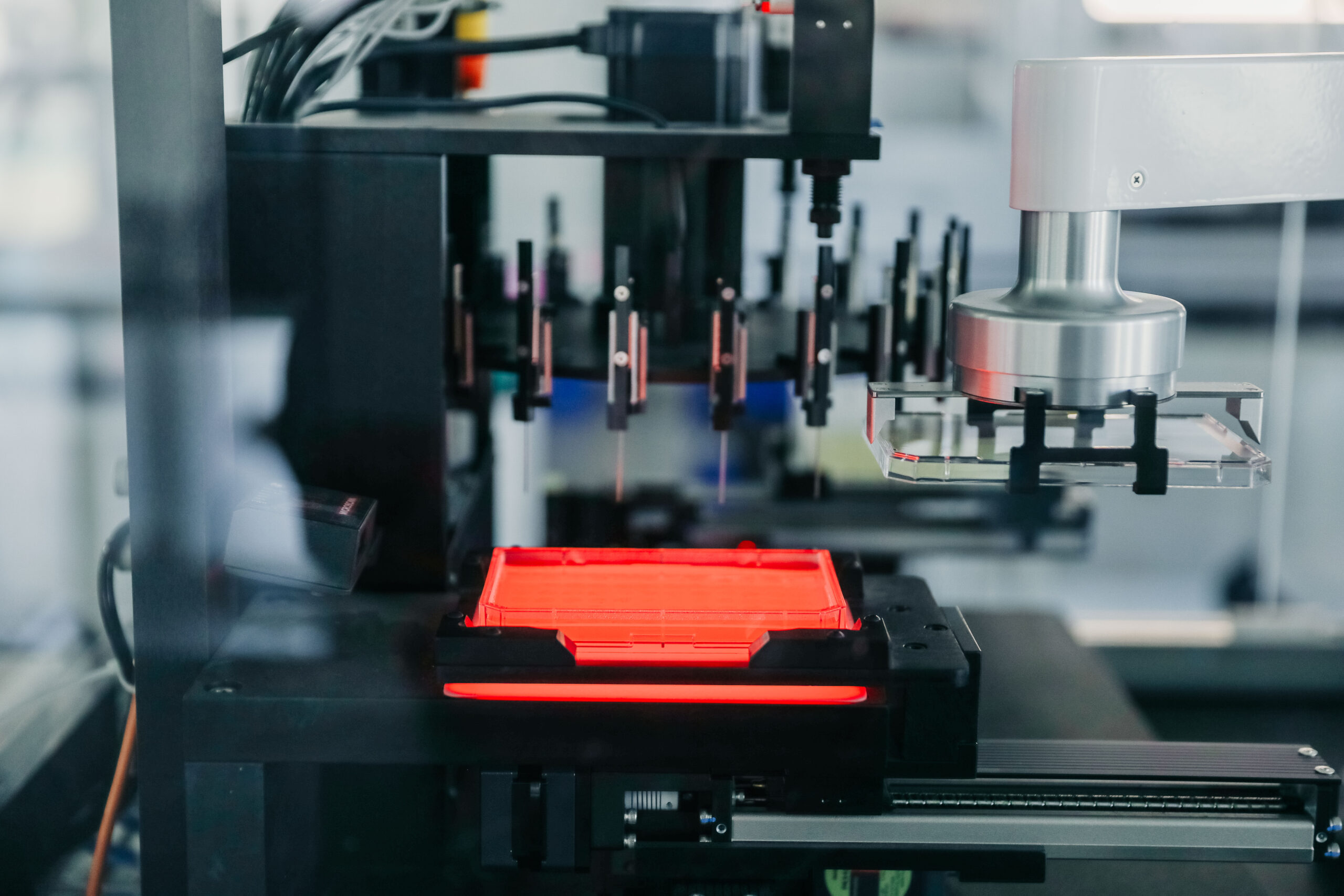

Our in-house developed Biofoundry platform combines computer algorithms and state-of-the-art biotechnologies, accelerating DBTL (Design-Build-Test-Learn) cycles, enabling cleaner and more efficient biomanufacturing, realizing “Idea to Scale to Commercialization”.

Our foundry |

Bota Biofoundry is a full-stack software-driving-hardware integration

Cell2Cloud@Design

Enable the genomic engineering of microbes through computer aided DESIGN and programming driven BUILD

Cell2Cloud@Scale

Streamline TEST data collection to LEARN the best screening candidates and process optimization opportunities.

Enable the genomic engineering of microbes through computer aided DESIGN and programming driven BUILD

Cell2Cloud@Scale

Streamline TEST data collection to LEARN the best screening candidates and process optimization opportunities.

Design Principles

Magnitude Acceleration

1. Modular platform to adapt to versatile product opportunities and microbes

2. Continuous innovation to drive down per-unit cost of high-throughput operations

3. Robust correlation to transit from plates to tanks to pilot plant

4. Large-scale high-quality AI-ready datasets to enable enzyme & pathway analysis

Robust correlation

Modular platform

Lower per-unit cost

AI-ready datasets

Magnitude Acceleration

Bota redefines the DBTL principles to accelerate the discovery of one-in-a-million by orders of magnitude

Cell2Cloud@Design

translates DNA designs

into machine-readable scripts

With C2C@Design driving the automated workstations, the throughput of building DNA constructs has drastically increased 100-fold.

Scientists spend 30 seconds instead of 30 minutes designing each DNA construct using the Fiddle programming language.

Scientists spend 30 seconds instead of 30 minutes designing each DNA construct using the Fiddle programming language.

Cell2Cloud@Design

Industry’s best enzyme library construction

C2C@Design generates complex enzyme (Site saturation mutagenesis & Combinatorial mutagenesis) library designs , supporting the industry’s best 16-fragment assembly to cover the entire space.

C2C@Design can continuously self-improve the predictive power of its algorithms based on actual data to warn of potential failures.

C2C@Design can continuously self-improve the predictive power of its algorithms based on actual data to warn of potential failures.

Cell2Cloud@Scale

Co-pilot for experiment design and data analysis

Digital experiment traveler simulates screening conditions and recipes for each step in the workflow.

Automated statistical process control drives the Auto Pick to validate the HTS results without human bias

Automated statistical process control drives the Auto Pick to validate the HTS results without human bias